Why Choose DPES?

We advises and assists customers in a full range of automation, switchgear, and controls solutions. Our solutions are designed with you the customer in mind.

We advises and assists customers in a full range of automation, switchgear, and controls solutions. Our solutions are designed with you the customer in mind.

DePeuter Electrical Solutions, LLC. (DPES) designs and builds switchgear, AC and DC drives, PLC based control systems and provides electrical installation as well as project management services.

To provide you, Our Customer, the best fully integrated and customized automation solutions available. And to provide all our employees with a challenging and rewarding place of work, where critical and out of the box thinking is encouraged.

Bring easy to use and operate automated solutions to a variety of industries while continuing to be a leader in product development. Provide superior before and after sales service, with 24/7 technical assistance, and up to date training programs. Design, engineer, and build in USA.

Originally the company was founded in March 2009, as "DePeuter Electrical Solutions" (DPES). At the beginning of 2014 we split our company to differentiate our services and the name DePeuter Packaging Solutions (DPPS) was registered

to better match our new profile in the material handling segment. However, the company keeps the basic services of electrical solutions

Headquartered in Houston, DPES designs and builds switchgear, AC and DC drives, PLC based control systems and provides electrical installation as well as project management services.

DPES is very well positioned globally to serve its customers with custom and specialized solutions for their projects. We have been partnering with customers for more than 15 years.

DPES advises and assists customers in a full range of automation, switchgear, and controls solutions. Our solutions are designed with you the customer in mind. They all have one thing in common and that is that they are simple in design and operation. They are designed based on your needs, in a way that is very cost effective and allows for a fast delivery. We are committed to assisting customers worldwide with their unique needs by providing them with comprehensive, value-added solutions and professional service.

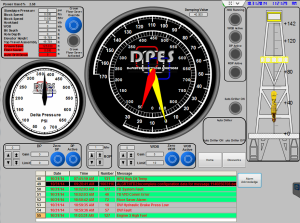

DePeuter Electrical Solutions has now developed and implemented a smart, easy to use, fully integrated drilling control system. This new system INFINITE™ possibilities.

All control systems, data logging, cameras and maintenance programs are integrated into one platform. Giving the operator an INFINITE™ range of possibilities to not only control the rig but to maintain it as

well.

Some of the highlighted features available are:

The DPES ACEMS system consist of 2 systems that can be installed independent of each other. The ACEMS systems is easily integrated into the DPES INFINITE™ control

system, but can also be adapted to existing rigs and control systems.

The Zone Management part of ACEMS controls the movement of all drillfloor equipment that is integrated into the system, like a piperacker, stabbing arm, catwalk, floorhand. It will prevent collision of any of

these items with the vertical traveling equipment.

The Anti Collison System, controls the speed of the block travelling through the mast, based on inputs from the zone management system (when included), floor saver set-point, crown saver set-point, hookload,

and block position.

All equipment movement will be stopped in case of a safety zone violation

Features: